Performance and reliability testing

and evaluation technologies

Yutaka has equipment that can perform a wide range of tests from material function evaluation to

product performance and reliability evaluation.

With such equipment, the developed products are verified to guarantee performance and reliability.

Motor System

Motor bench

Dedicated equipment that can perform performance measurement and durability testing for

motors and their assemblies.

This equipment can measure motor efficiency and rpm-torque characteristics.

It also enables programmed operation with a durability testing mode that simulates the

actual vehicle operation.

-

Dynamometer:

Small/medium 100 kW-20,000 rpm

Large 300 kW-25,000 rpm

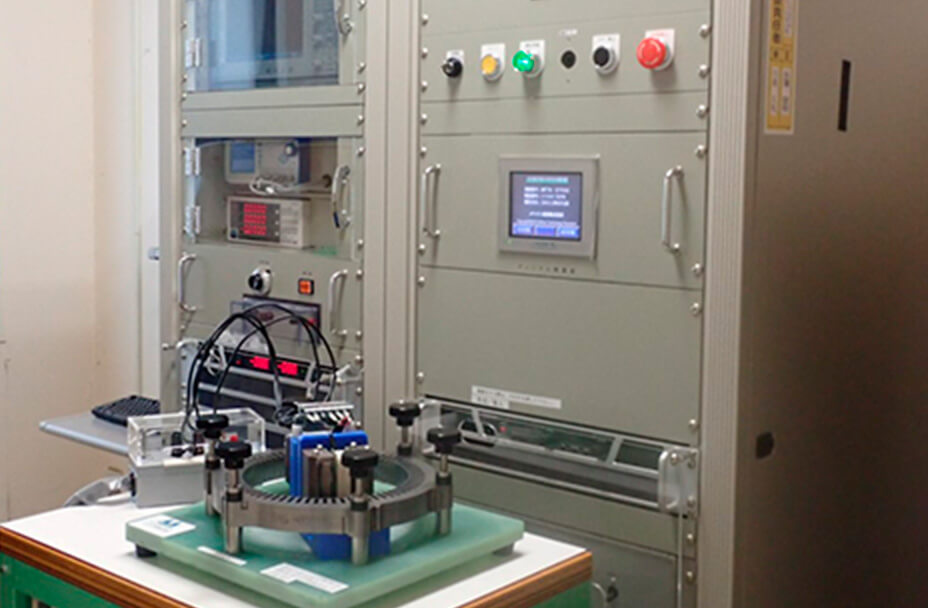

AC/DC magnetization measuring instrument

Equipment used to measure the magnetic characteristics of electromagnetic steel sheets

with an Epstein test frame, single sheet frame, and dedicated frame.

This equipment can measure the magnetic flux density, iron loss (W/Kg), and hysteresis

curves with varying excitation frequencies.

(Excitation frequency: 40 to 20 KHz)

Impulse tester

The tester used to inspect stators, inductors, and other motor parts for insulation

failures between windings.

Using the waveform obtained by applying an impulse to a non-defective product as a

reference (master waveform), the waveform and area are compared to make a pass/fail

judgment.

(Applied voltage: 100 to 4,200 V)

Partial discharge tester

Equipment used to detect partial discharge that takes place when an impulse signal is

applied to a stator winding.

This equipment can identify latent defects in a coil by detecting partial discharge.

(Applied voltage: 500 to 5,000 V)

Brake System

Disc brake tester

Special equipment can perform performance measurement and durability testing for

motorcycle disc brakes.

This equipment can measure the friction coefficient, braking torque and disc pad

temperature under input conditions (rpm, braking pressure and air resistance).

It also enables programmed operation with a durability testing mode that simulates

actual vehicle operation.

(Traction motor: 55 kW)

Drive System

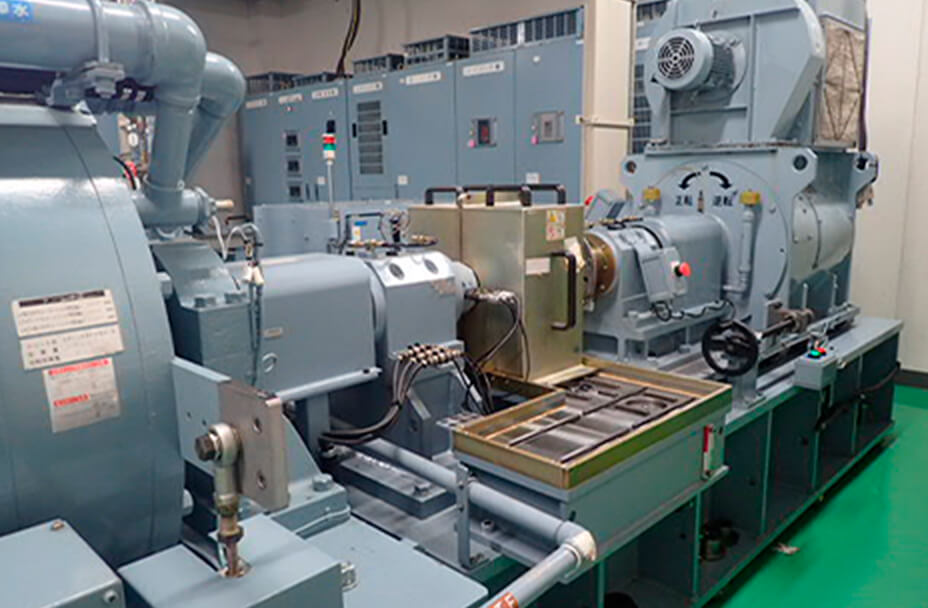

Torque converter performance tester

Special equipment that can perform performance measurement and durability testing for

torque converters.

This equipment can measure the capacity coefficient, torque ratio, clutch capacity, and

the performance of other parameters under input conditions (rpm, torque, oil pressure,

and oil temperature).

It also enables programmed operation with a durability testing mode that simulates

actual vehicle operation.

(Traction motor: Small 45 kW Medium 160 kW Large 300 kW)

Rotational torsion vibrator

Equipment that can be used to subject torque converters and flywheels to rpm

fluctuations to measure the attenuation rate and test their durability.

The attenuation rate can be assessed by measuring the fluctuations in rpm and torque

under the input conditions (rpm fluctuation, torque fluctuation, oil pressure, and oil

temperature).

It also enables programmed operation with a durability testing mode that simulates

engine rpm fluctuations and torque fluctuations.

(Traction motor: 450 kW)

Thermal Management

Pressure pulsation tester

Equipment used to evaluate toughness against the water pressure of parts assembled into

the vehicle coolant circuit.

This equipment pressurizes and decompresses a heat exchanger repeatedly to evaluate its

reliability after many pressure fluctuations.

It can generate high-speed (up to 6 Hz) pulses, thereby shortening the test period.

- Pressure: 0 to 1.0 MPa

- Frequency: 0 to 6 Hz

- Waveform: Sine wave, trapezoid wave, square wave, triangular wave

Heat recovery performance measuring instrument

Equipment used to feed air or cooling water to heat exchangers evaluates their heat recovery performance. This equipment consists of the optimal heating/cooling device, flowmeter and temperature sensor for air and cooling water and can accurately measure the amount of heat recovered. Also, this equipment provides an environmental tester and can simulate an extremely cold environment of -30°C.

- Air: Temperature Room temperature to 500°C / Flow rate 0.5 to 40 g/s

- Cooling water: Temperature -10 to 80°C / Flow rate 0.1 to 25 L/min

- Atmosphere: -30°C to room temperature

Exhaust System

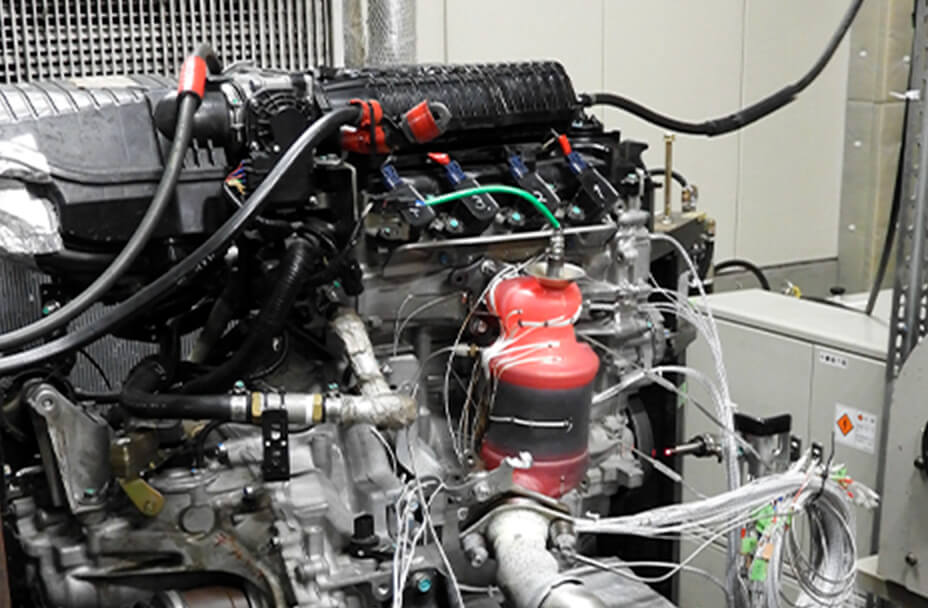

Engine bench

Equipment used to test vibration, heat, and exhaust pressure of engines.

This equipment simulates the actual vehicle installation state, and with an AC

dynamometer, is available in various test modes.

- Engine bench: 3 units

- Dynamometer: 220 kw, 280 kw, 370 kw

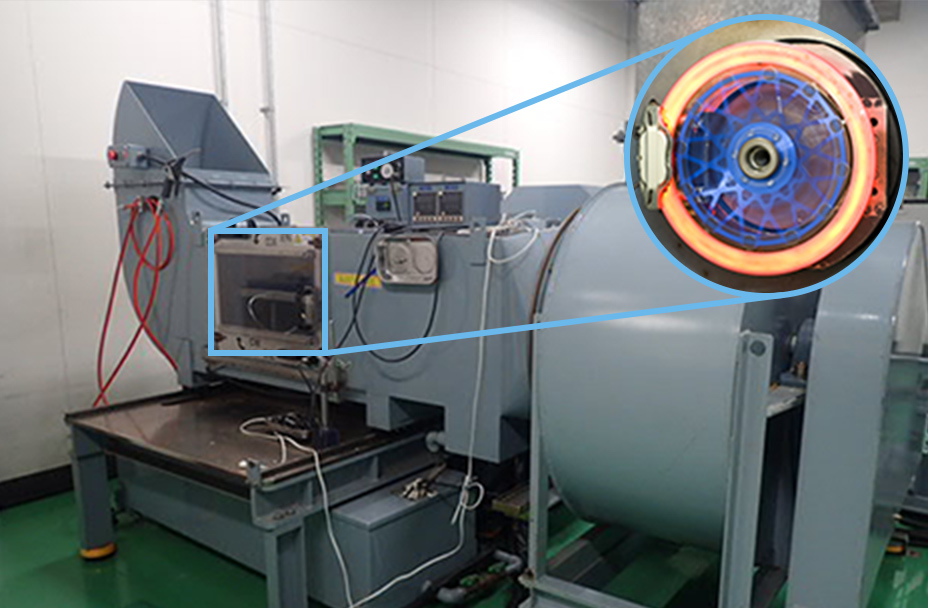

Exhaust gas simulator

Equipment used to perform high-temperature vibration testing by using a combustor and

electromagnetic vibrator to simulate an engine. When the hot/cold cycle is simulated,

the sample can be cooled down rapidly, thereby shortening the test period. Only thermal

testing or vibration testing can be performed by removing the unnecessary

equipment.

<Combustor>

- Temperature: 500 to 1,100°C

- Flow rate: 30 to 280 g/s

- Pressure: Up to 100 kPa

<Vibrator>

- Frequency: 5 to 2,600 Hz

- Acceleration: Up to 964 m/s2

Rough road simulator

Equipment used to simulate the behavior of the engine and chassis while the vehicle is running on a rough road and to evaluate the durability of exhaust parts. This equipment can simulate the behavior of an actual vehicle, without the actual vehicle and the rough roads testings.

- Engine side: Six vibrators are used to simulate six degrees of freedom (applicable to not only exhaust parts but also other parts).

- Suspension point side: Two vibrators are used to simulate two degrees of freedom. Provided for five sets.

- Displacement: ±75 mm Acceleration: ±50 G (Engine side) ±20 G (Suspension point side)

- Frequency: Up to 60 Hz

- Temperature: Ambient temperature

Anechoic room bench

Equipment is used to replicate vehicle exhaust noise by connecting the engine to a

dynamometer to simulate the vehicle’s operation.

The engine is placed in a dynamometer room while the sample is in an anechoic room to

evaluate exhaust noise without interference.

- Anechoic room bench: 2 units

- Anechoic room: Six-sided anechoic room Background noise NC-20

- Dynamometer: 415 kW, 300 kW

Design CAE analysis

Yutaka is using CAE to verify performance and reliability for each model during the design stage for efficient development.

Sites in Japan

Overseas Sites

If you have any orders or inquiries