Press Processing

Press Processing

Yutaka has a system in place for mass production of stamped products with its own dies.

Yutaka can offer optimal process design with various thicknesses, materials, and production

systems, that incorporates CAE (analytical technique).

Technologies supporting stamping.

- Laminating press

- Self-manufacture of dies

- Precision processing

- Precision measurement

- CAE analysis

- Lamination manufacturing method

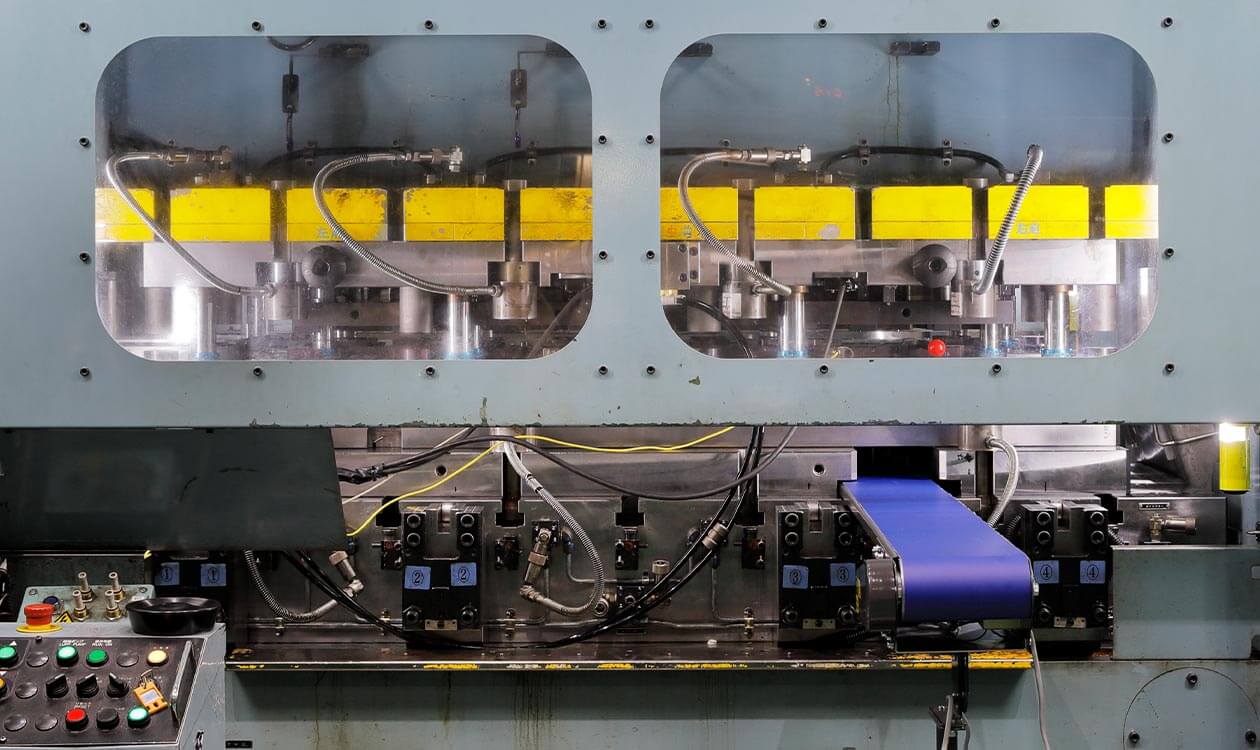

Laminating press

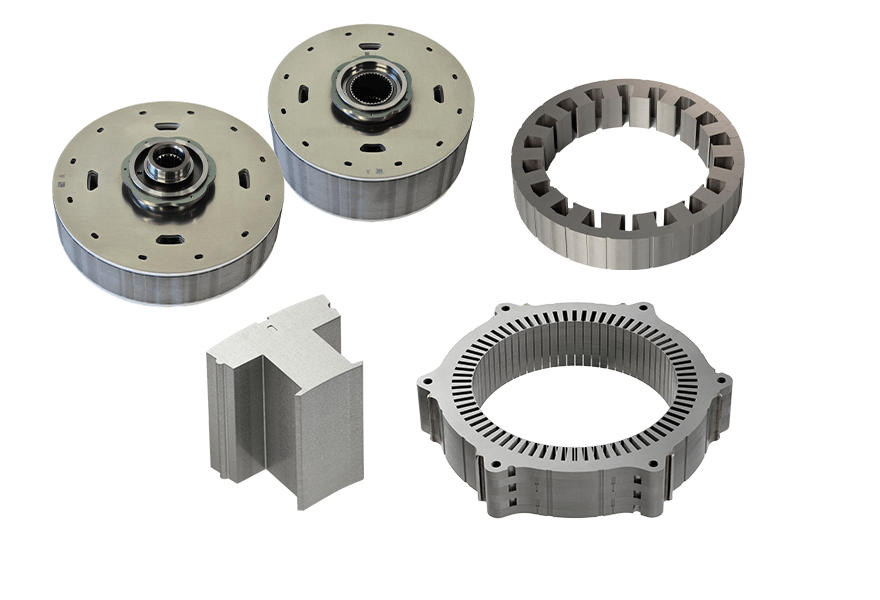

Yutaka has successfully produced T-core products based on one-point riveting lamination, which is its proprietary manufacturing process.

Yutaka also produces rotor and stator cores through composite lamination production with high-precision, high-speed large presses.

With production being supported by maintenance equipment such as large precision surface grinding machines and ultrasonic washing machines, Yutaka has established a maintenance method by which everything is completed within.

The introduction of a new TRY press has enabled the following advantages: trial runs equivalent to mass production and the timely launch of mass production.

Equipment

Introduction of low-cost equipment

Enhanced with UG expertise to achieve processing performance comparable to Japanese-made presses.

TRY Press MCP-400

Bolster size 3700×1200

-

MSP-4000

Bolster size 3360×1200 -

MSP-2200

Bolster size 2000×1000 -

Large precision surface grinding machine

-

Ultrasonic washing machine

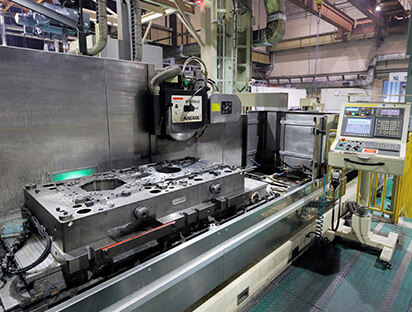

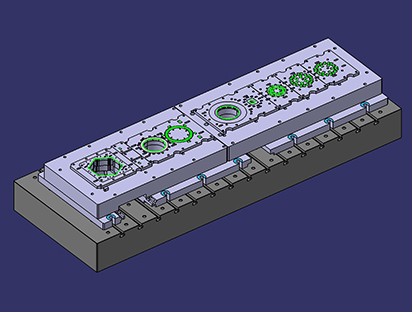

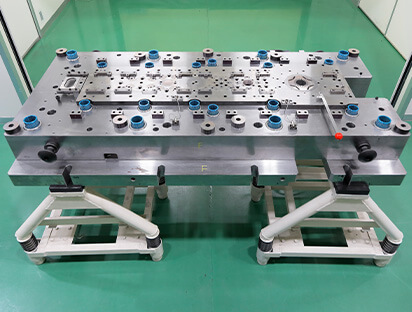

Self-manufacture of dies

Yutaka now manufactures its own laminating dies, which includes the processes of Planning and design → Production → Assembly and Try.

Yutaka is working hard to enhance its technical capabilities and competitiveness through

enhancement of its ability to come up with ideas for new manufacturing processes and new

structures and proposal of low-cost manufacturing processes.

Why does Yutaka manufacture its own dies?

Yutaka’s ownership is evidence of continual technical capabilities.

Enhancing new manufacturing processes, and new structures, and offering VA proposals

Establishing a global backup framework

Maintaining and managing stable mass production and implementing improvement measures completely on its own

Low-cost dies

Embodying its cost reduction concept and strengthening its ability to work with manufacturers

Human resource development

Early training and education based on “genba” (actual place), “genbutsu” (actual thing) and “genjitsu” (actual situation)

Equipment

-

CAE/die design

-

Precision processing

-

Adjustment/measurement

-

Trial/mass production

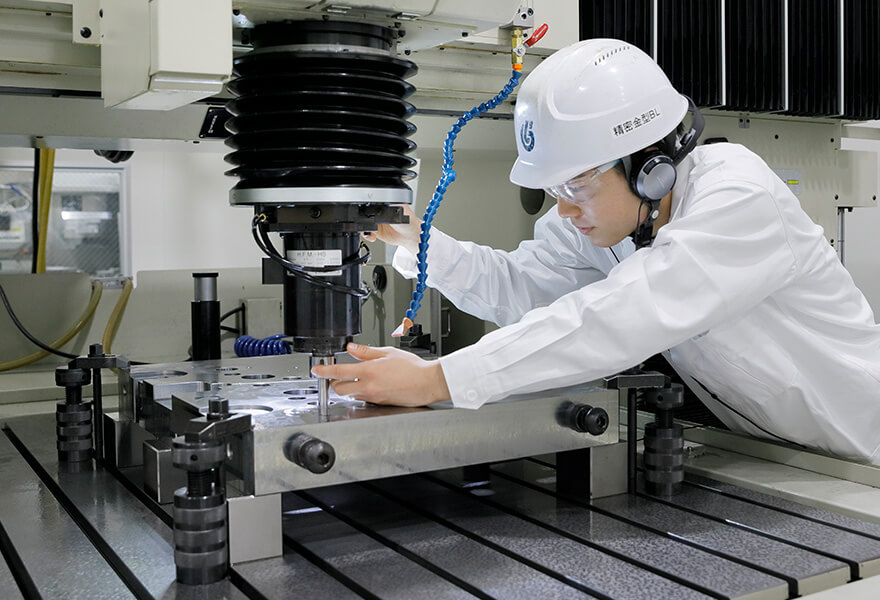

Precision processing

Yutaka's large processing machines enable us to processing large parts precisely (±2

μm). Processable range 1,580 mm × 1,020 mm

Yutaka has achieved a processing precision of ±1 μm through ultra-high precision

processing with wire-discharge processing machines.

High-precision processing has been achieved through the accumulation of processing

knowhow by experienced operators.

Equipment

-

Maximum processable range: X1,580 mm Y1,020 mm

Processing precision: ±2 μm

Temperature control: 23°C±1°C -

High-precision die parts processing (punch die)

Temperature control: 23°C±1°C -

Maximum processable range: X800 mm Y600 mm (water type)

Processing precision: ±2 μm

Temperature control: 23°C±1°C -

Chuck dimensions: X800 mm Y400 mm

Processing precision: ±2 μm

Temperature control: 23°C±1°C

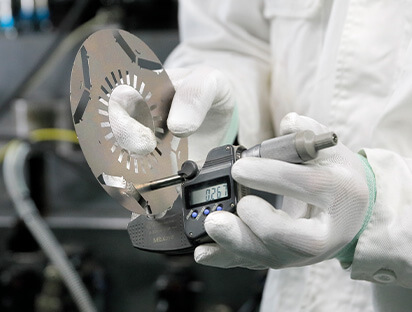

Precision measurement

With the experienced operator’s measurement precision of ±1 μm, micron-precision

three-dimensional measurement is possible.

The temperature and humidity are controlled at 20°C±1°C and 50%±10%, offering a good

measurement environment.

Extremely small styluses with a minimum diameter of 30 μm have enabled touch

measurement of extremely small shapes, thereby enabling measurement of extremely

small radiuses.

Equipment

-

Mitsutoyo

Coordinate measuring machineMeasurement range:

X-axis 900 ㎜

Y-axis 1000 ㎜

Z-axis 600 ㎜

Maximum workpiece height:

850 ㎜ -

Mitsutoyo

Quick Vision -

Mitsutoyo

Contour tracer -

Constant-temperature chamber

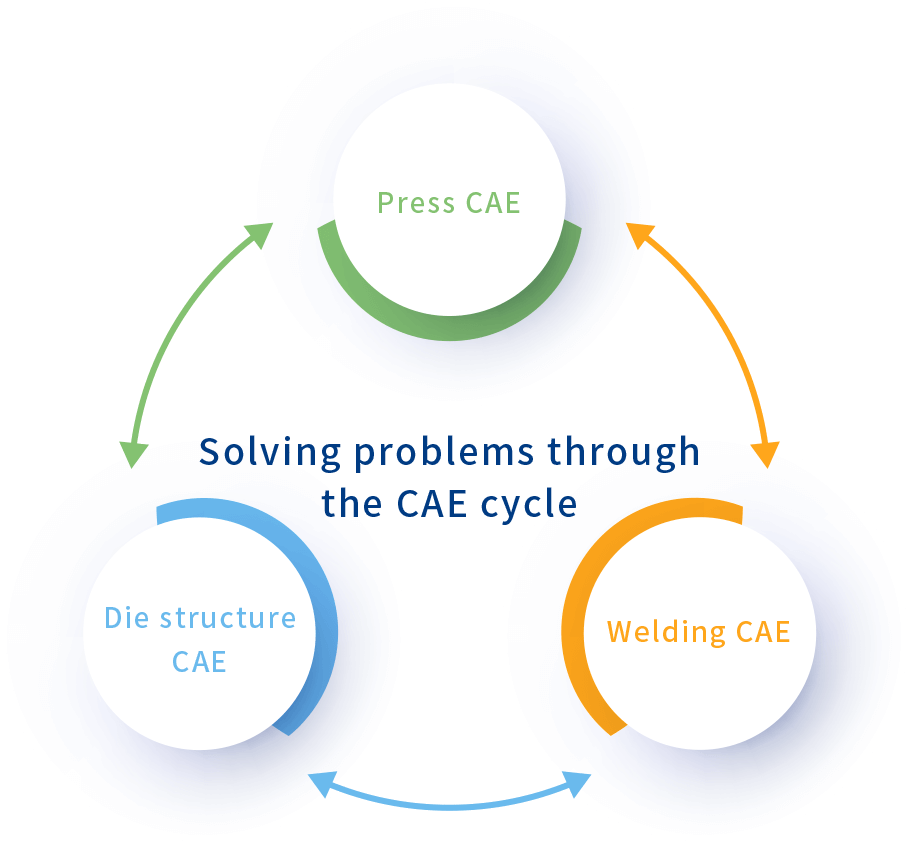

CAE analysis

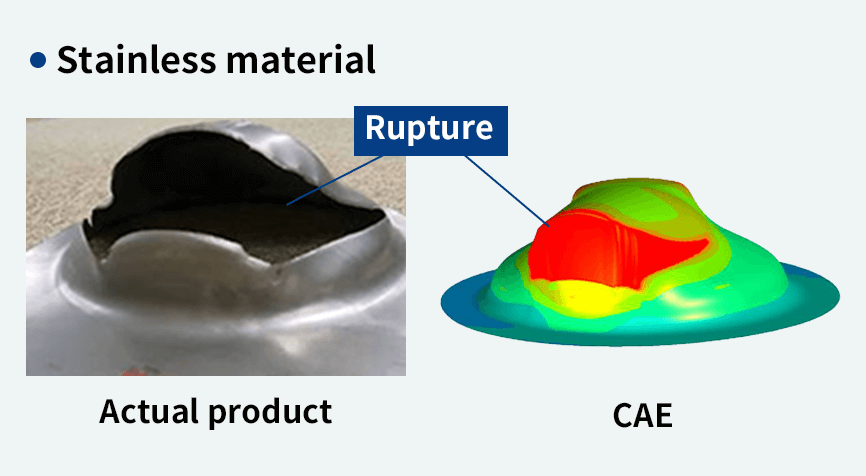

Through die process design, and press CAE, it is possible to analyze product

wrinkles, cracks, and spring back in plate stamping.

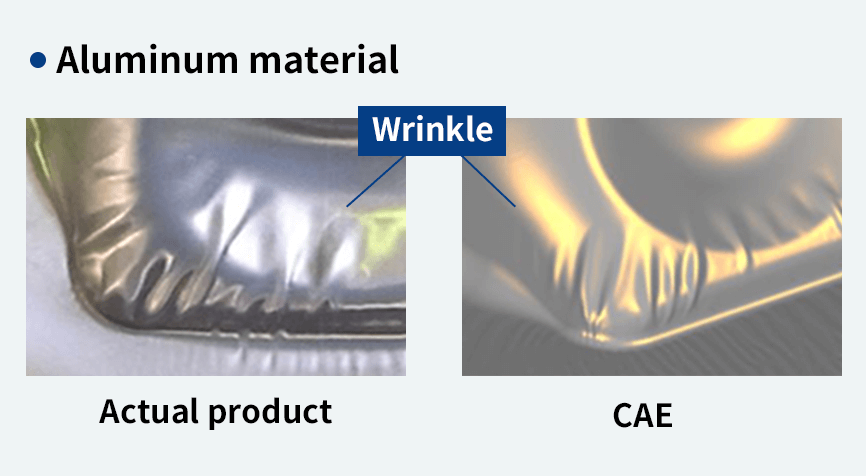

Through die design with die structure CAE, it is possible to analyze die

deformation, deflection, and stress.

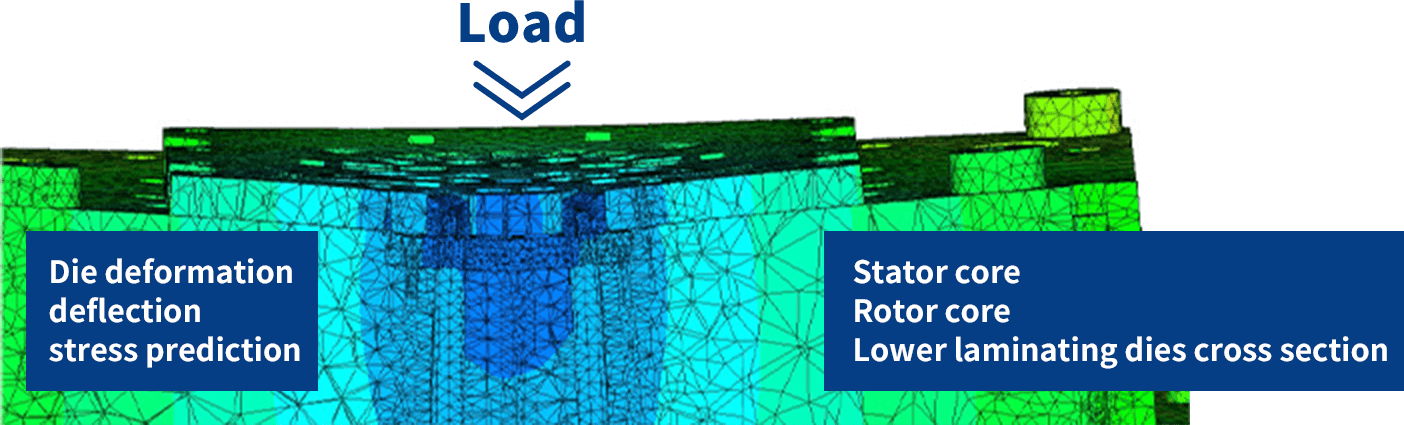

By reflecting product shapes obtained by welding CAE in dies, it is possible to

analyze thermal distortion, heat transfer, and temperature distribution after

product welding.

CAE

Press CAE

Offers accurate simulation without

differences from the actual equipment

Die structure CAE

Welding CAE

Lamination manufacturing method

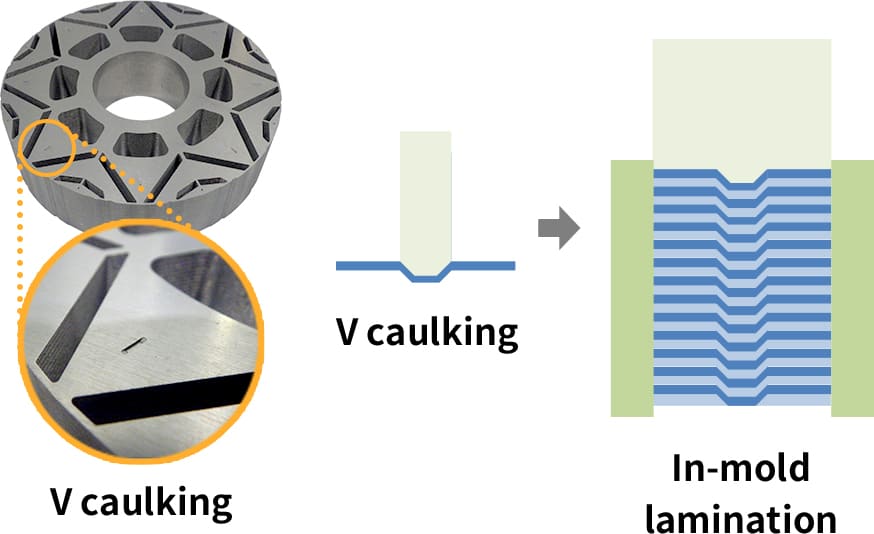

V caulking method

By prototyping and evaluating several types of V caulking shapes, we achieve the V caulking method that is optimal for a given product.

By forming V caulking, it is possible to secure sufficient caulking strength and mass-produce the product in a stable manner.

We have succeeded in laminating particularly thin sheets(t=0.2) out of the types of electromagnetic steel sheets.

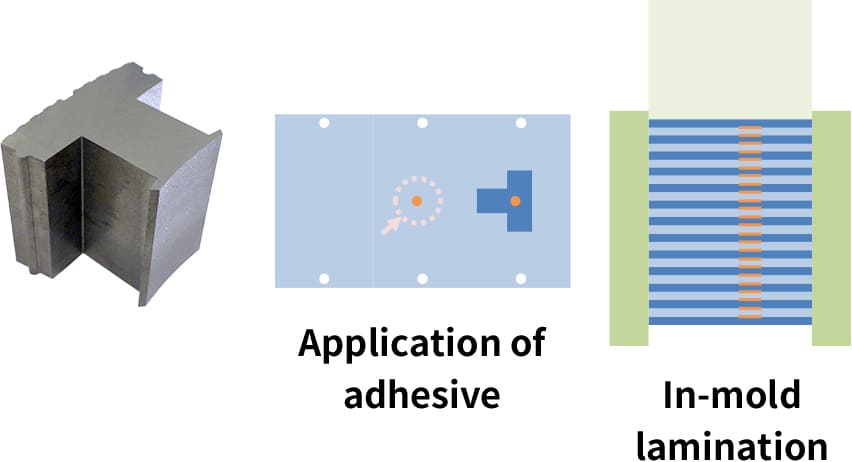

Adhesion lamination method

With our proprietary adhesion mechanism for bonding between laminated sheets equipped inside a mold, we have established the adhesion lamination method.

Compared to caulking and welding, the adhesive lamination suppresses iron loss and improves the motor efficiency.

Sites in Japan

Overseas Sites

If you have any orders or inquiries