Joining Technology

joining technology

Yutaka has a wide range of joining technologies, including digital analysis, brazing, and riveting, with various welding techniques and CAE.

Technologies supporting joining.

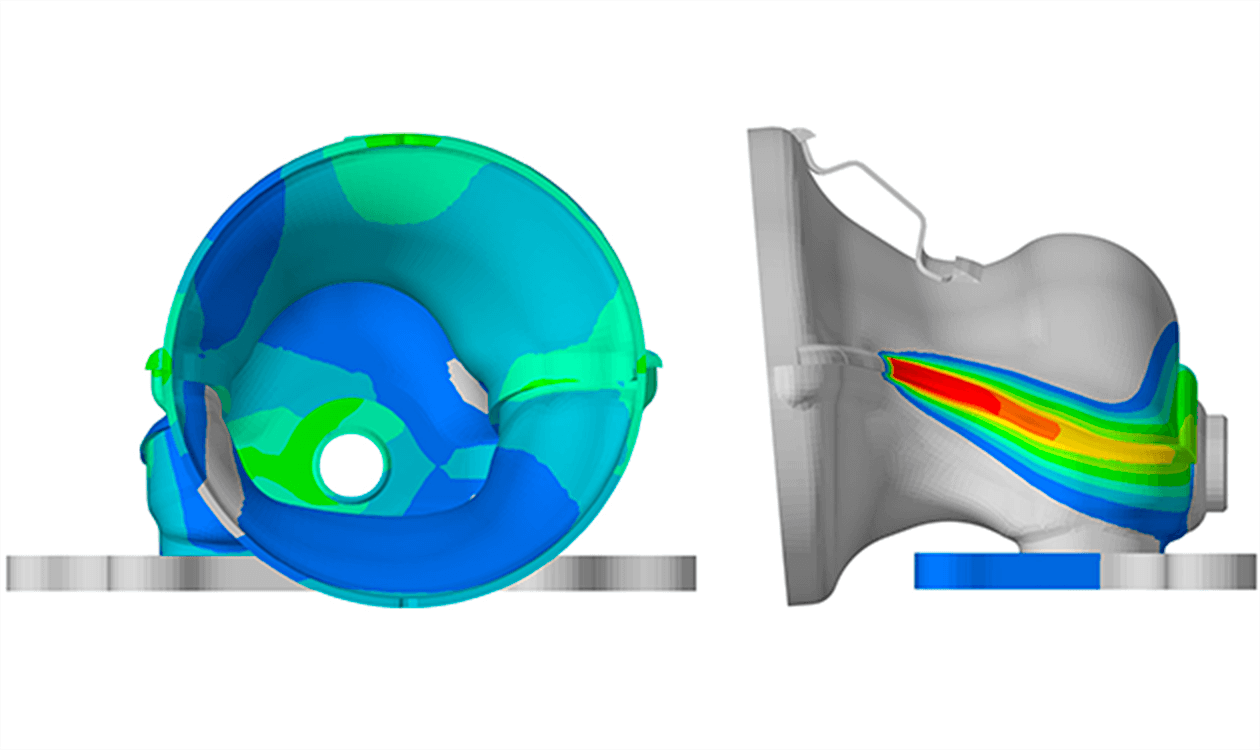

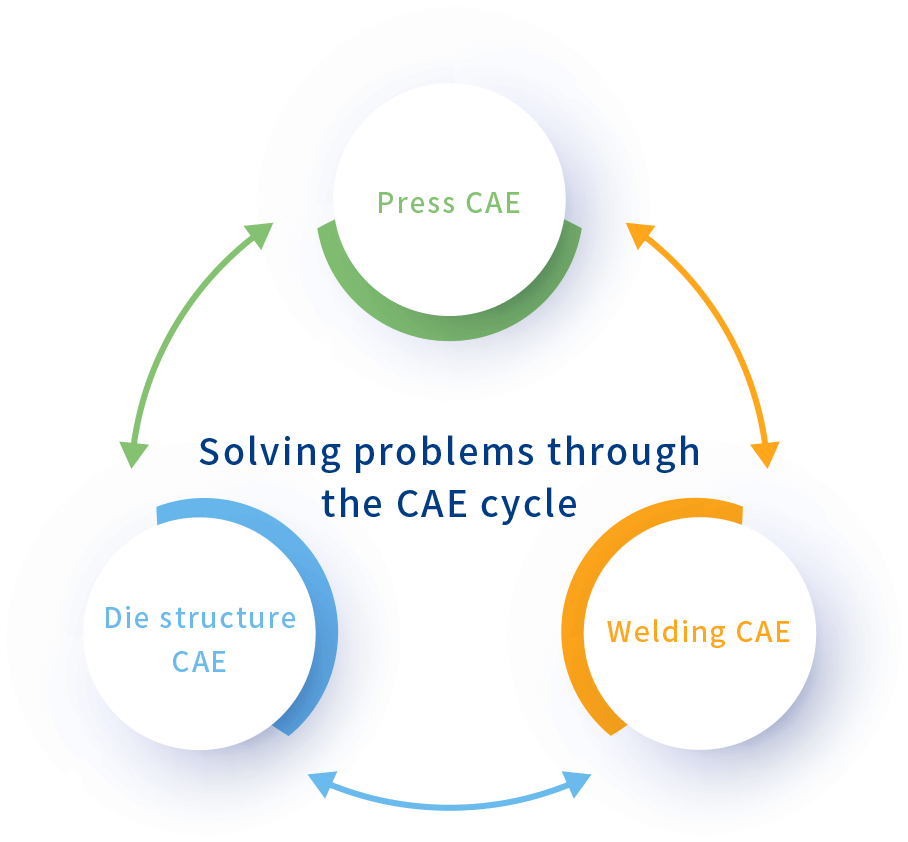

CAE analysis

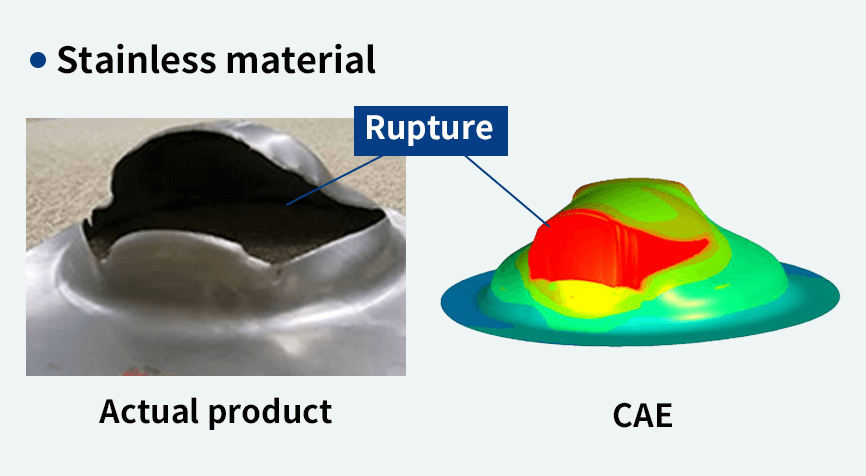

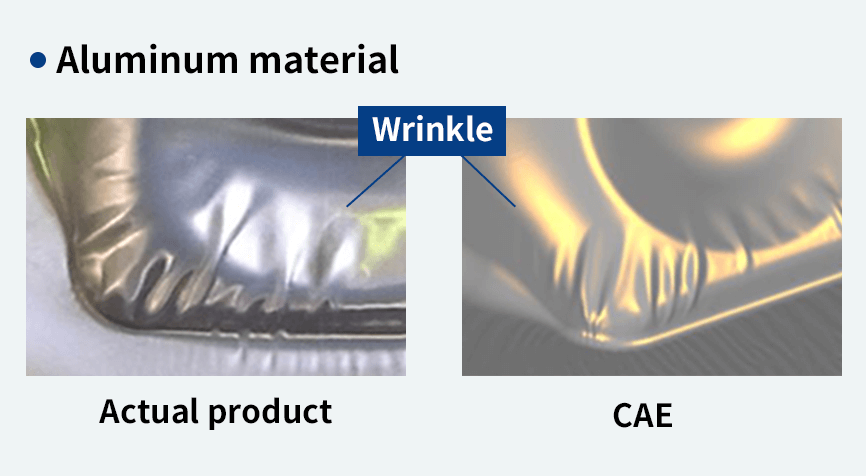

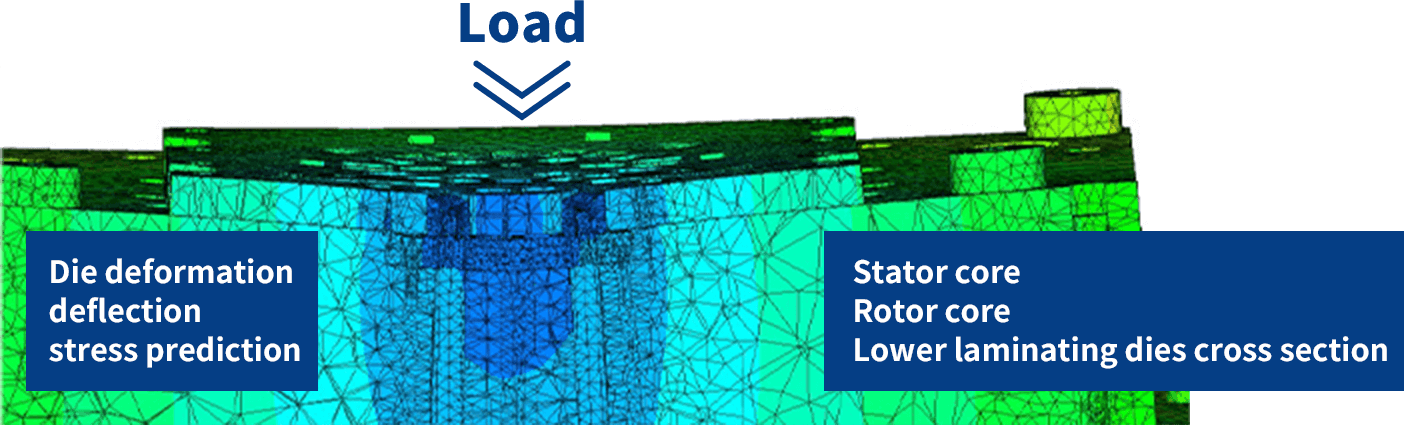

Through die process design, and with press CAE, it is possible to analyze product

wrinkles, cracks, and spring back in plate stamping.

Through die design with die structure CAE, it is possible to analyze die

deformation, deflection, and stress.

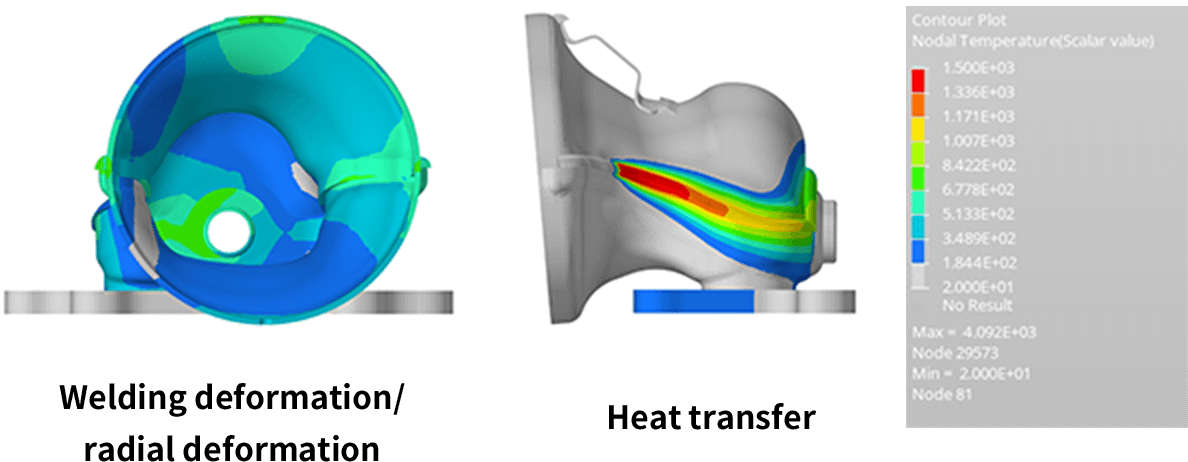

By reflecting product shapes obtained by welding CAE in dies, it is possible to

analyze thermal distortion, heat transfer, and temperature distribution after

product welding.

CAE

Press CAE

Offers accurate simulation without

differences from the actual equipment

Die structure CAE

Welding CAE

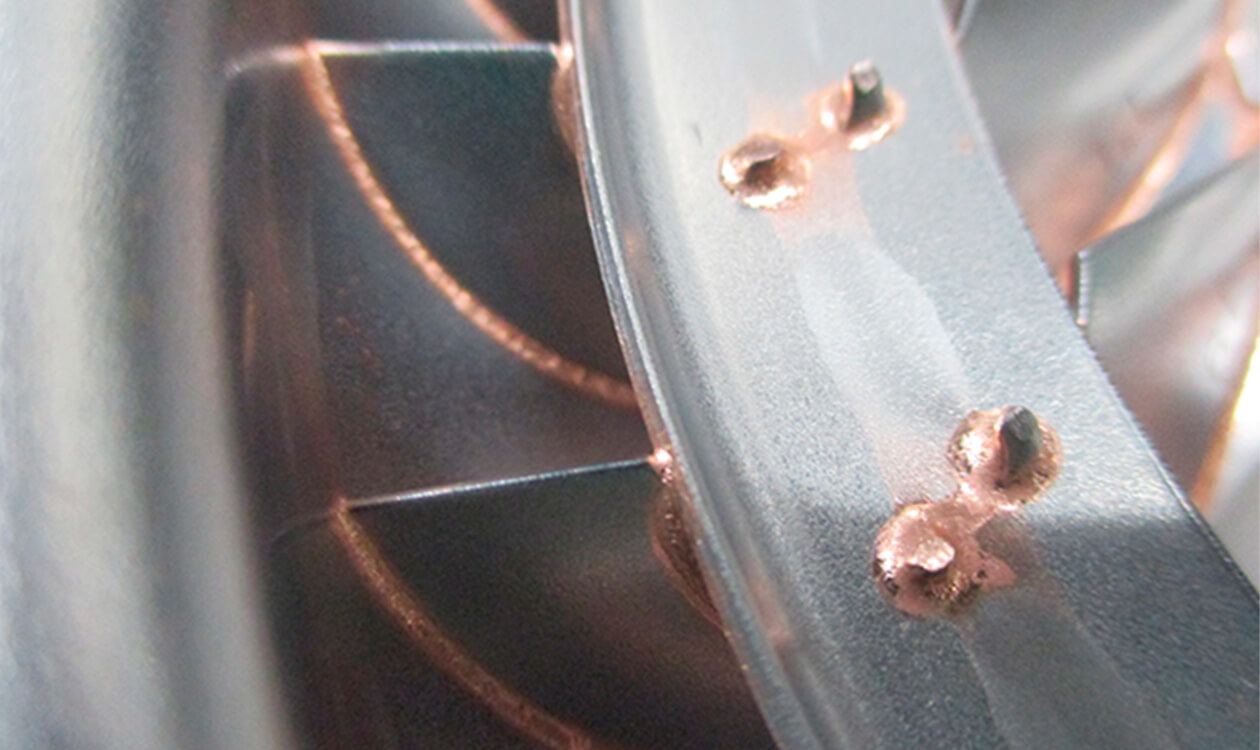

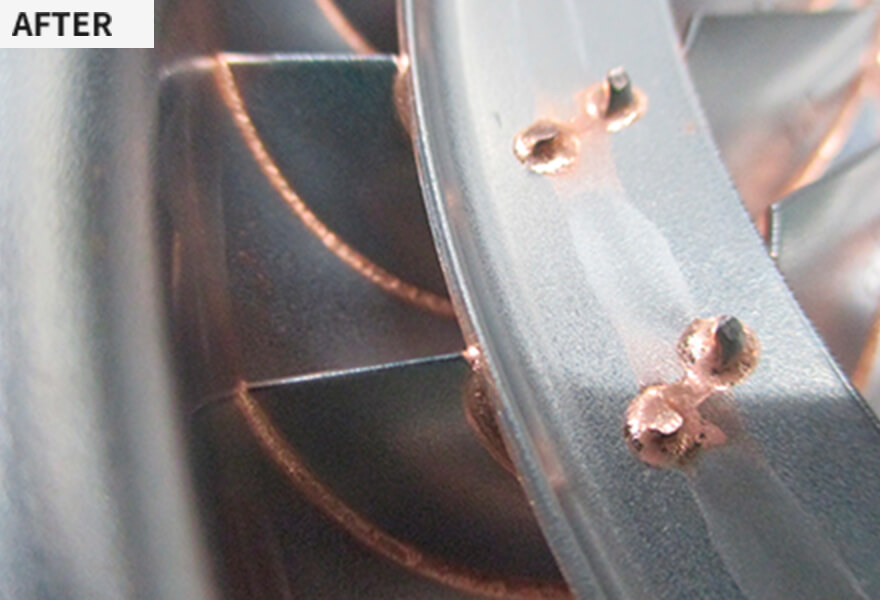

Brazing

Brazing is a technique that uses capillary action to cause a molten brazing filler

metal to penetrate between two materials and join them.

Yutaka guarantees the product's strength by setting the optimal amount of brazing

filler metal and the optimal gap.

Equipment

-

Brazing

-

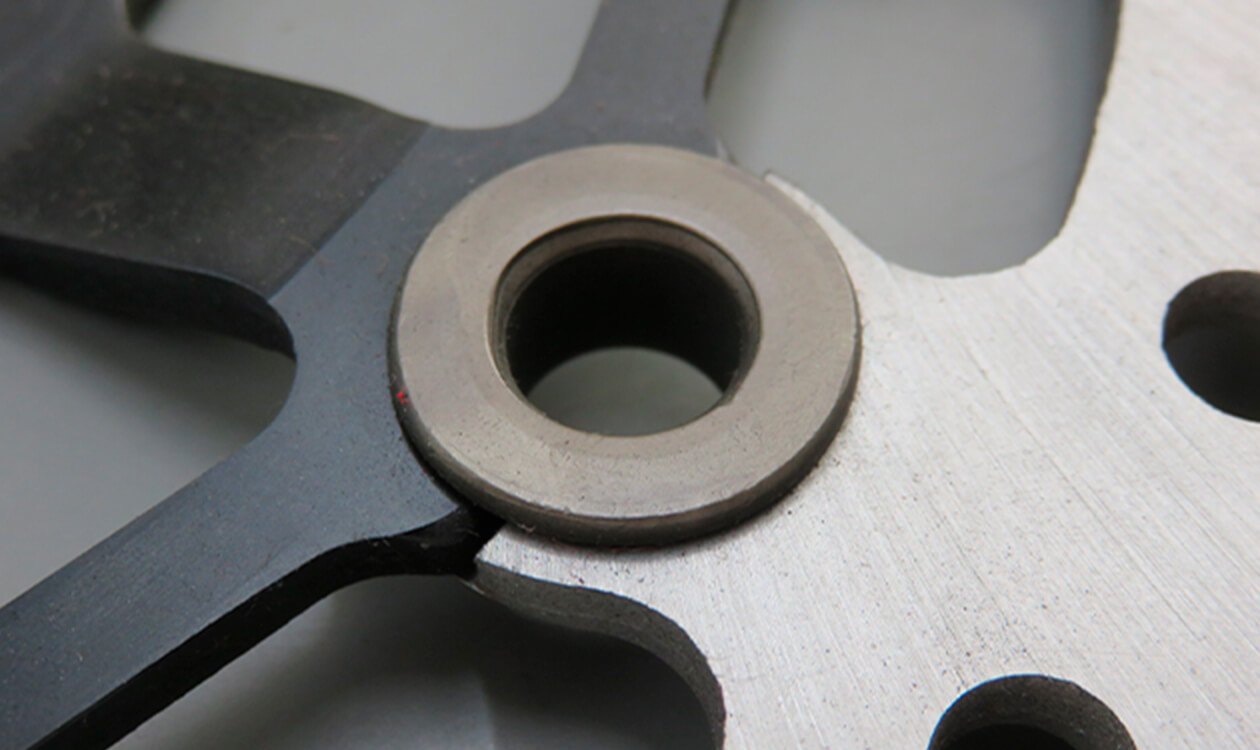

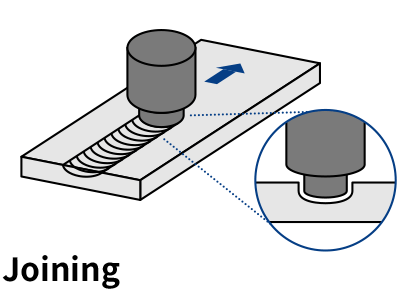

Riveting

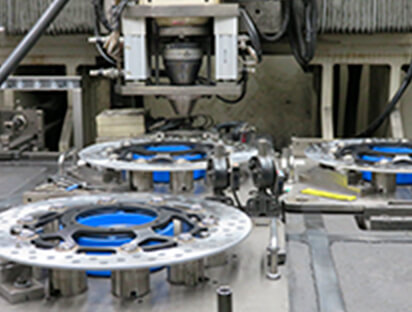

Rolling riveting, which is used for brake discs, is also used for aluminum

pins.

Yutaka's riveting technologies enable riveting without adverse effects on the

surface treatment of pins.

Equipment

-

Rolling riveting machine

(SUMIREX)

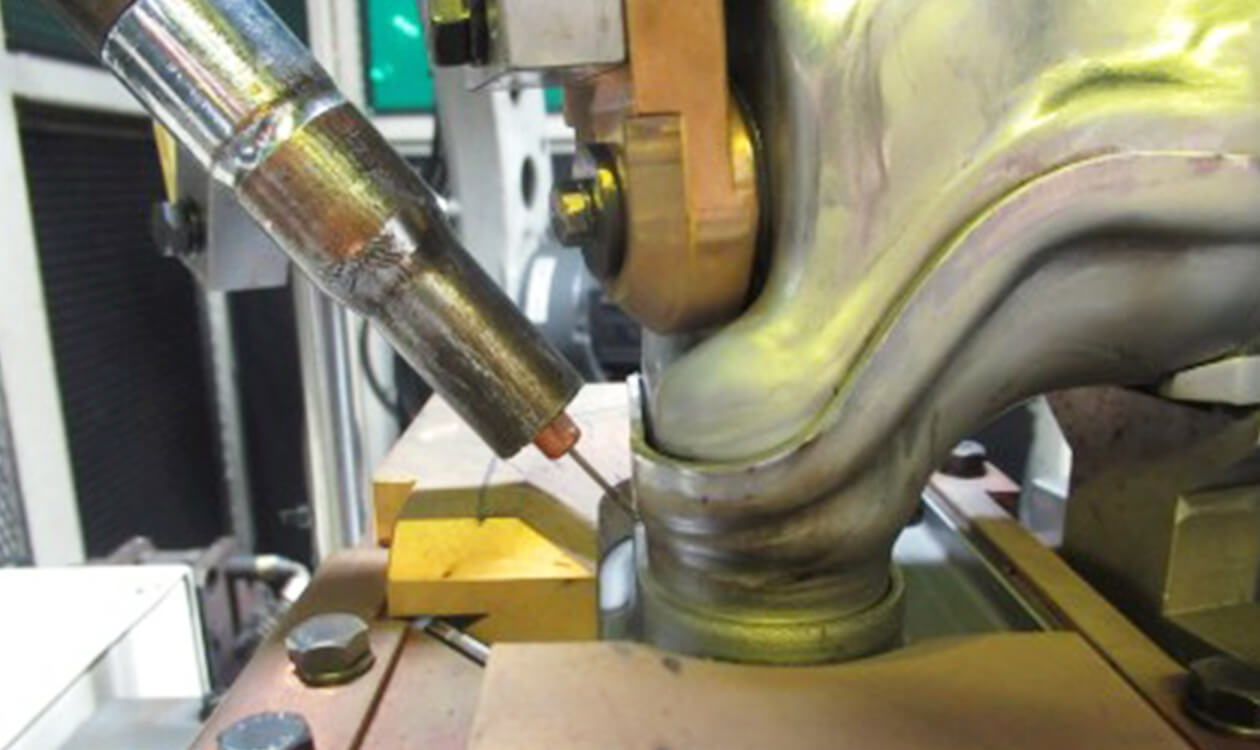

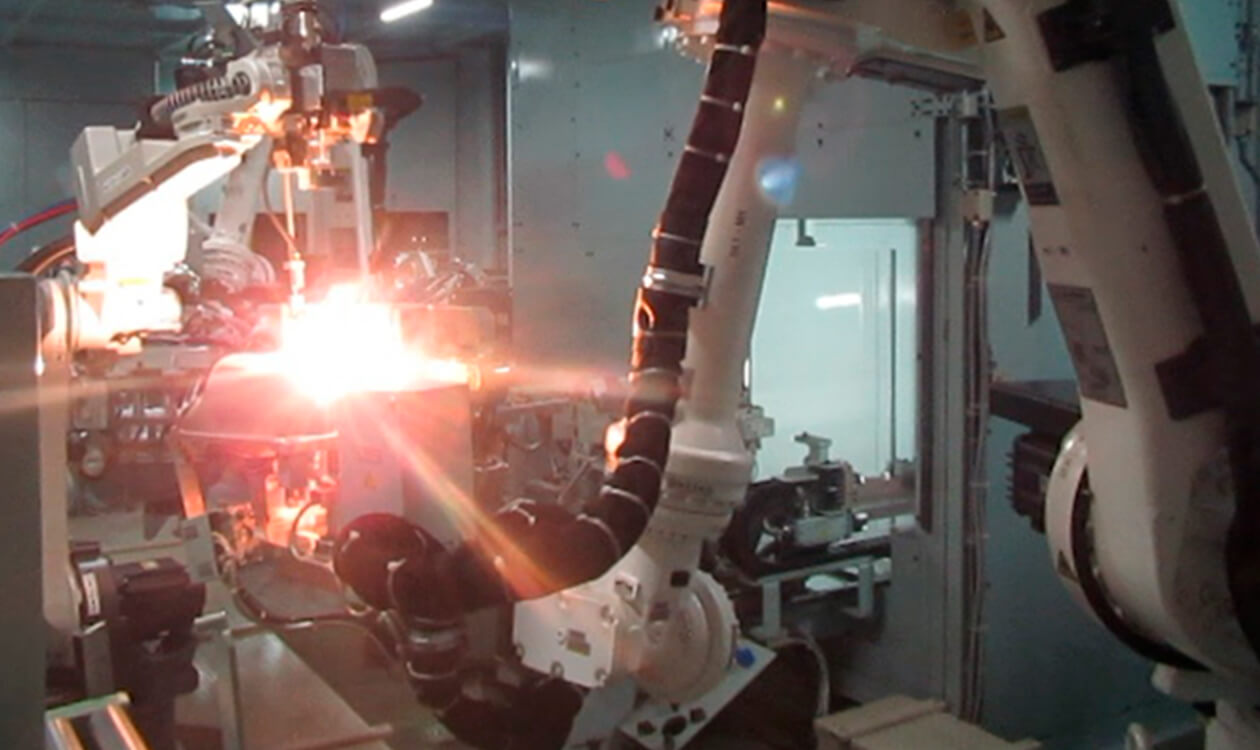

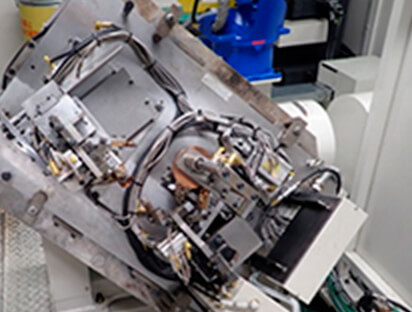

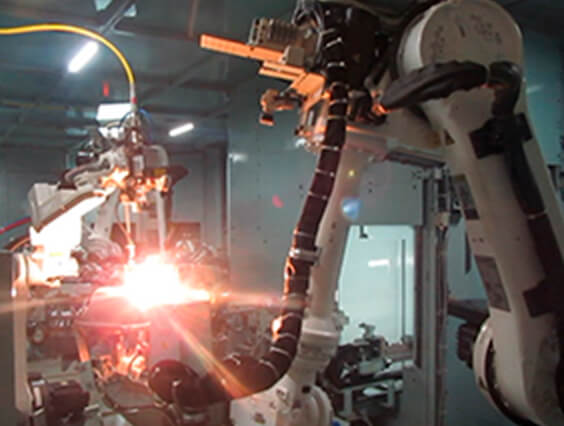

MAG welding

Yutaka excels in high-speed SUS thin plate welding, outperforming its rivals thanks

to the technology amassed through the mass manufacture of exhaust parts.

Yutaka offers a wide range of competitive welding methods, including those for

welding highly complex and challenging forms.

Equipment

-

Fixed table

-

1POS table

-

2POS table

-

Index table

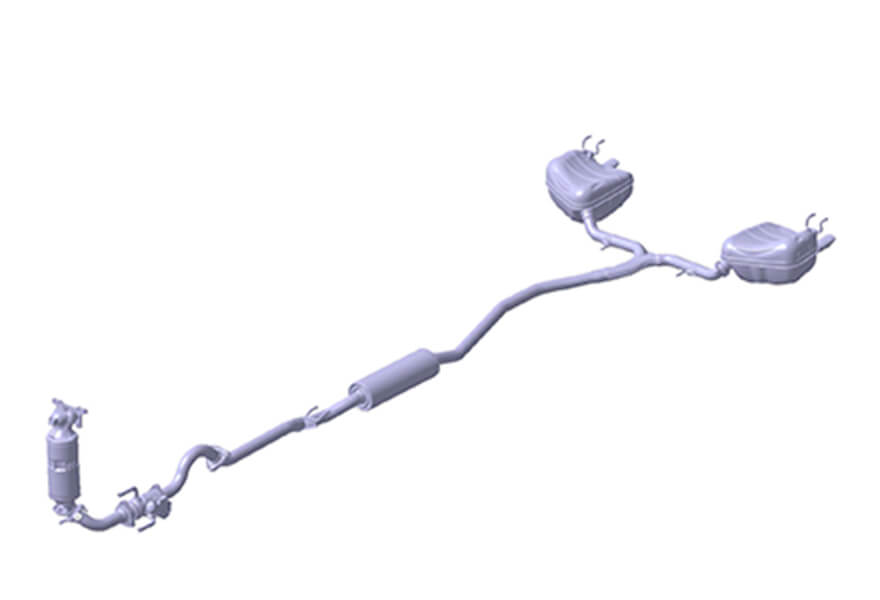

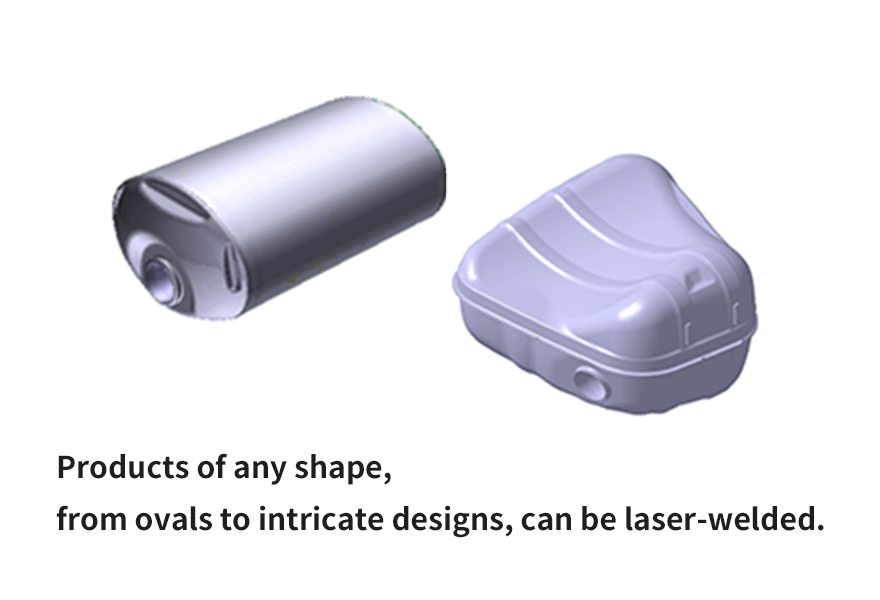

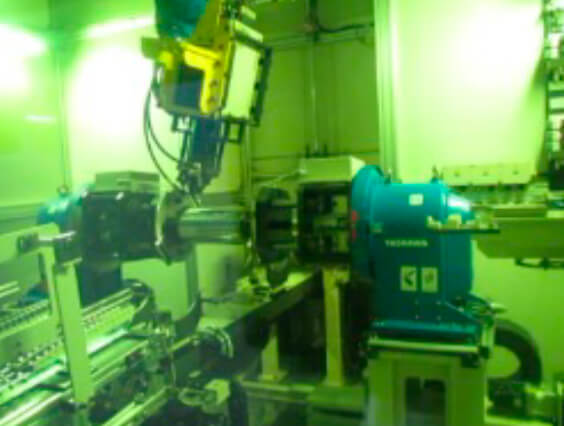

Laser welding

Yutaka uses the technology it's acquired from mass producing exhaust parts to

specialize in high-precision, high-speed welding of SUS thin plates.

Yutaka, including its foreign plants, has accomplished reliable manufacturing with

consistently high quality on a global scale.

Equipment

-

Laser equipment (oval silencer)

-

Laser equipment (press silencer)

-

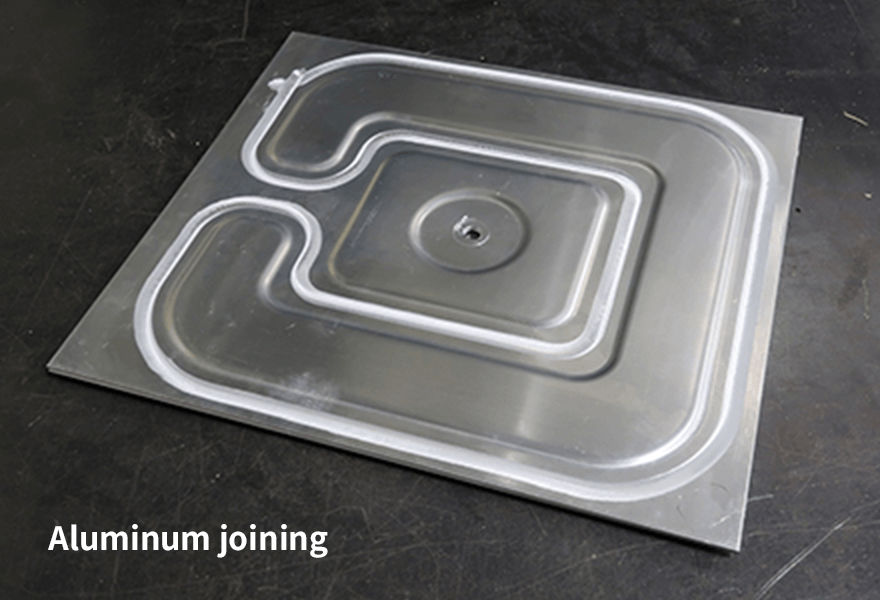

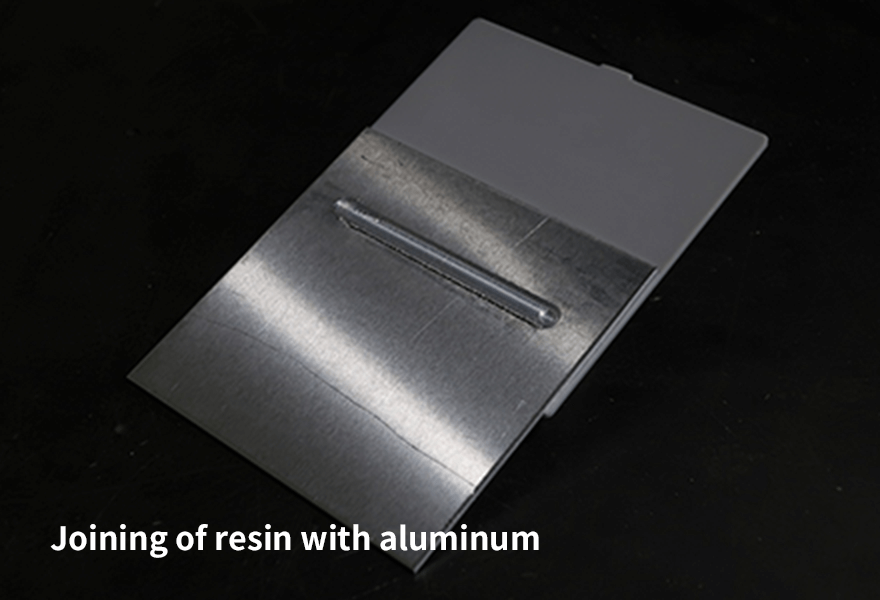

Friction stir welding

Inquisitive minds and taking up the challenge!

Yutaka is developing next

generation joining technologies that meet different product standards in an effort

to become a company with the best joining technology.

Manufacturing process

The technique of friction stir welding involves joining materials by softening

them with friction heat.

As a result, joining can be done at temperatures lower than those of welding,

which minimizes joining deformation.

This joining process is eco-friendly since it only uses the base materials and

doesn't utilize shield gas or any other components.

Sites in Japan

Overseas Sites

If you have any orders or inquiries