Motor System

motor system

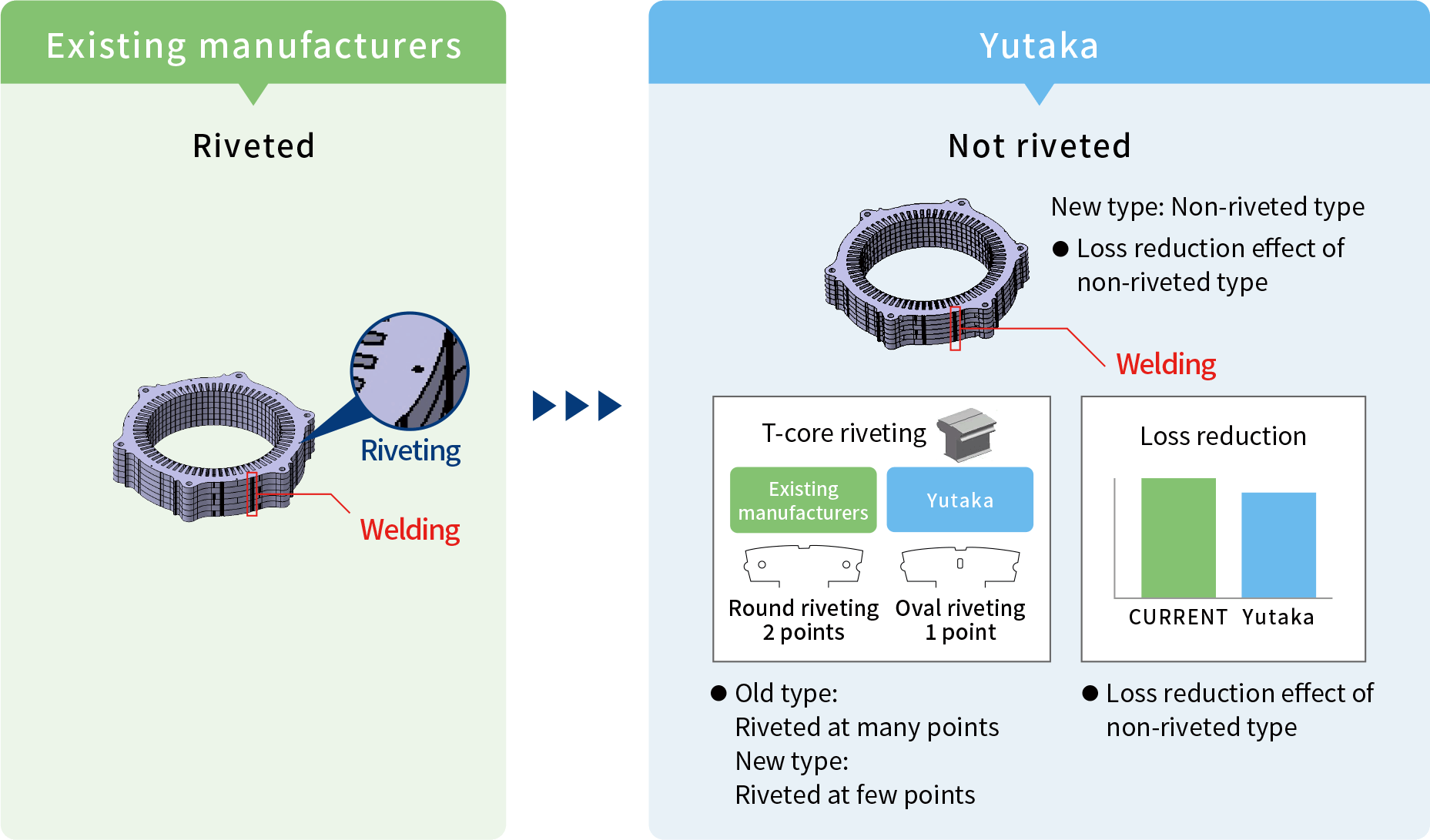

Yutaka's ultra-high-speed precision stamping technology has enabled high-quality, fully automated, stable production.

Yutaka will meet various customer needs.

Keywords

Motor System (Products)/Press Processing/Machining/Joining Technology /OEM/EV/Environmental Considerations/CAE

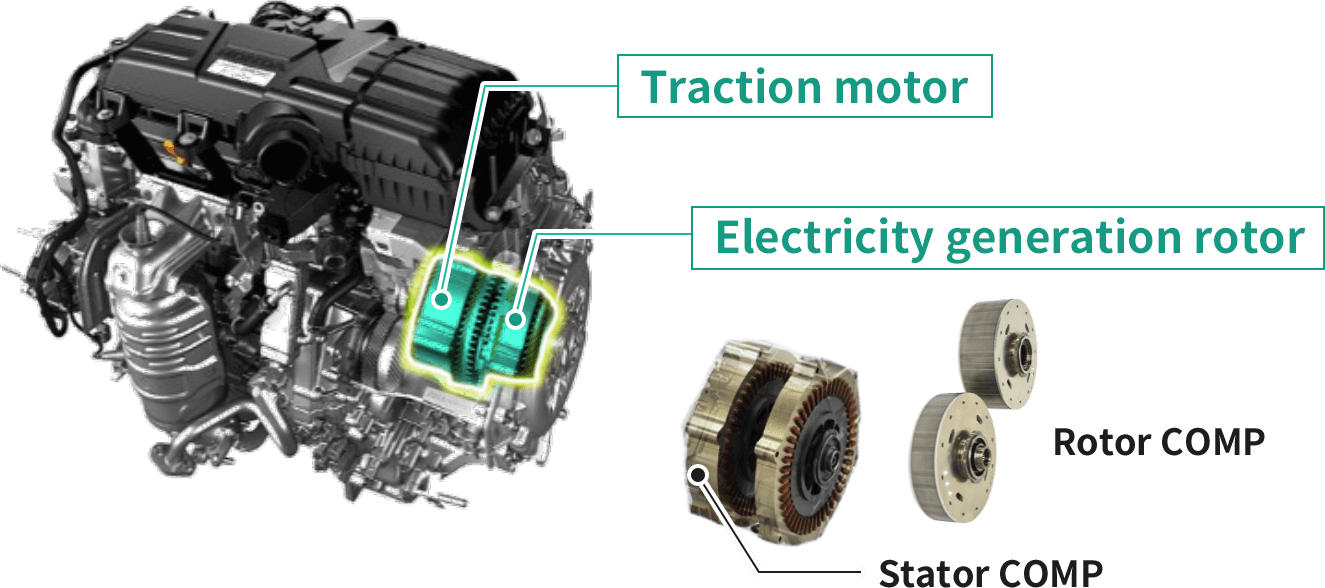

Yutaka's motor parts

Mounting position

Yutaka's strengths

Prototyping

Yutaka has medium- and large-sized high-speed laminating presses and prototypes various laminated parts. High quality is guaranteed with high-precision measuring machines with micron-level precision and performance measuring machines.

AC/DC magnetization measuring instrument,

Measures the iron loss of a laminated core.

Testing

Yutaka measures the iron loss of laminated parts, which effects motor efficiency, conducts strength testing, and feeds the results back into the product design.

Spin tester

Checks the high-speed strength of a rotor.

Product lineup

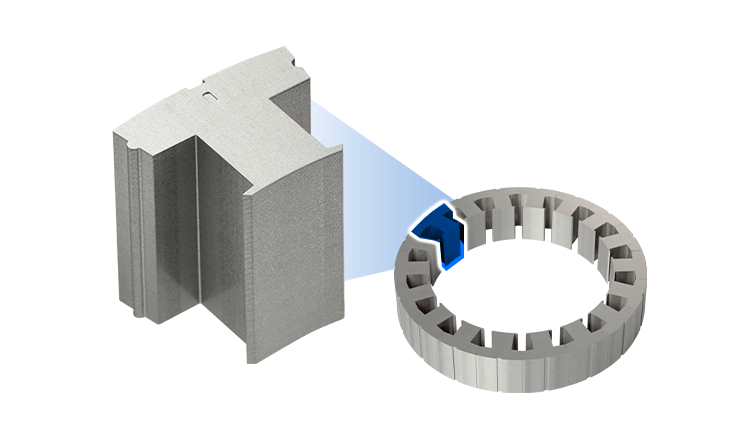

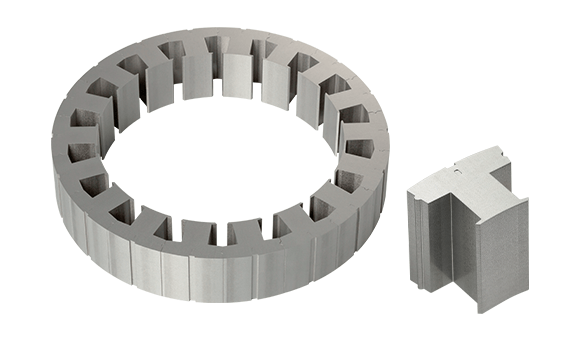

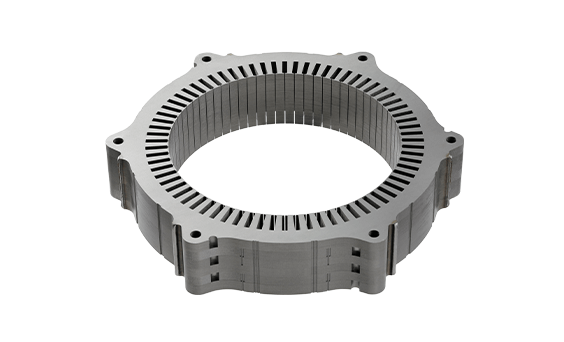

Stator SUB COMP

Stator SUB COMP

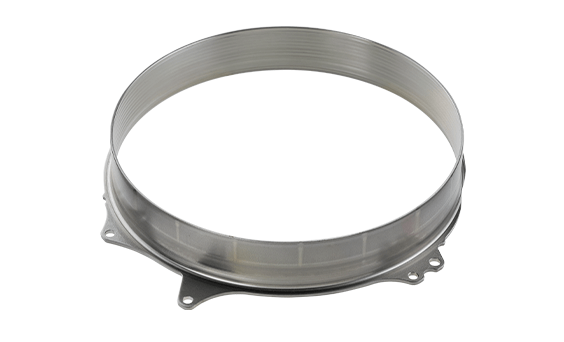

Stator holder

Stamping/machining

Magnet plate

Press

Material: SUS

Collar

Stamping/machining

Stator SUB COMP

Stamping/welding

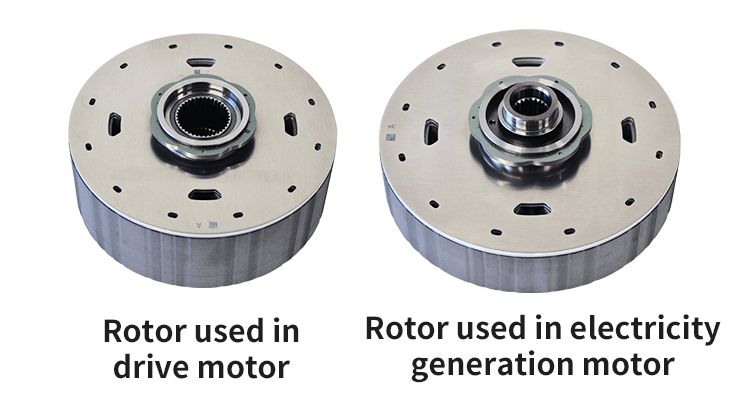

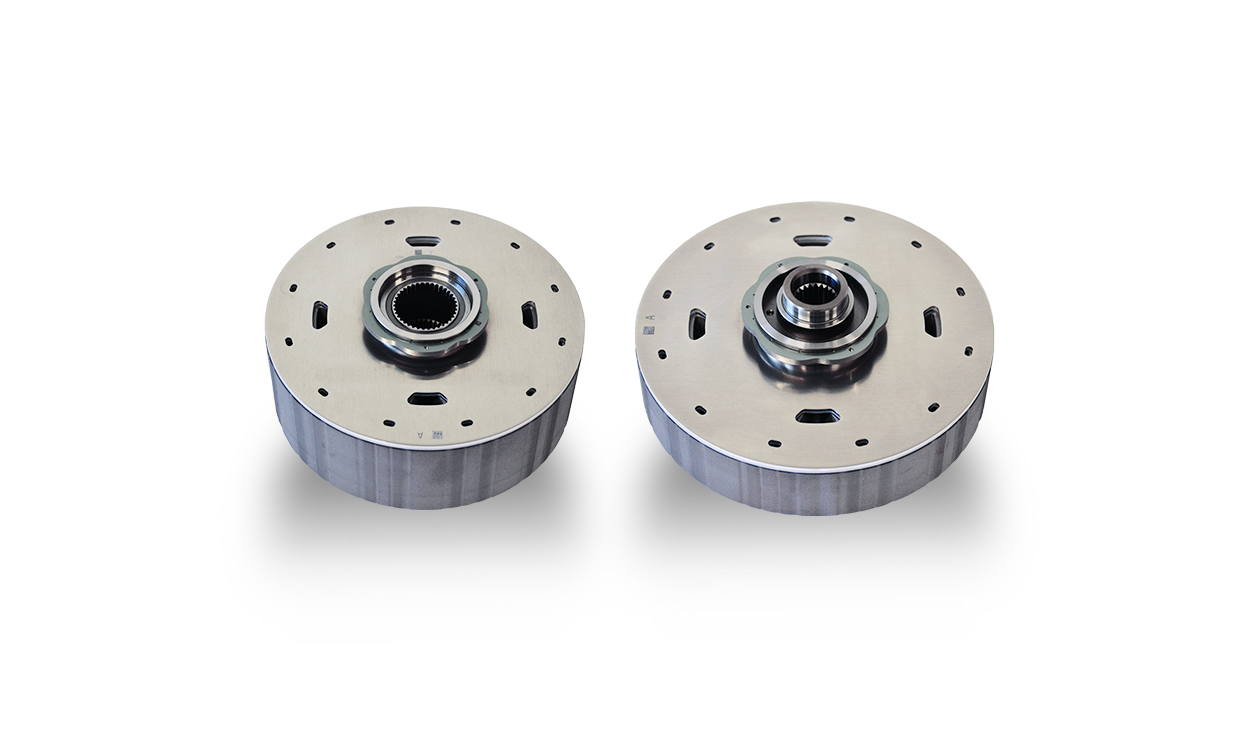

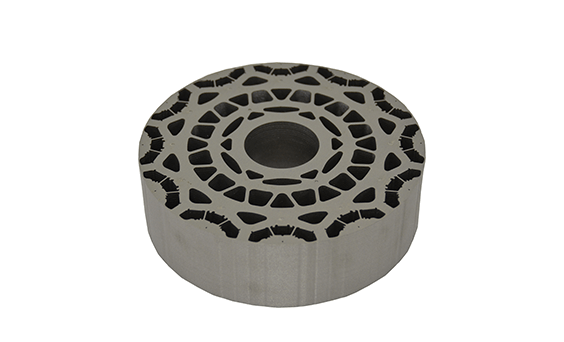

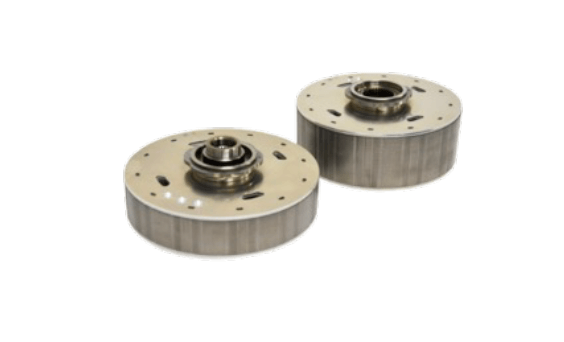

Rotor SUB COMP

Resin sealing

Rotor shaft

Machining/heat treatment

Produced by Shinnichi Kogyo (subsidiary)

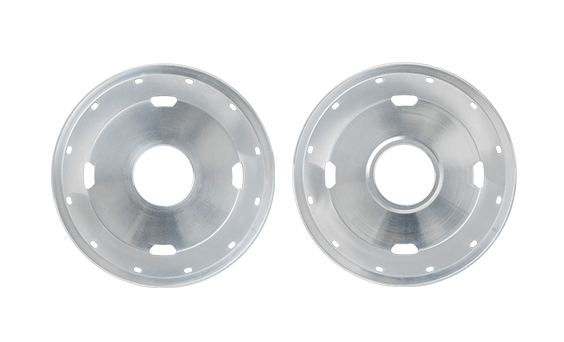

Magnet plate

Stamping/machining

Material: Aluminum

Rotor COMP

Assembly/press fitting

How Yutaka's motor parts Work (video)

Motor System Production Technologies

Press Processing/Machining/Joining Technology

Sales

Yutaka is expanding its motor business to achieve decarbonization in the future.

Yutaka has knowledge based on its experience and technological track record and offers proposals that can satisfy. Please feel free to consult us even in your development stage.

Also, Yutaka has many overseas factories and can offer proposals at a location that meets your needs.

Why not consider purchasing Yutaka's motor parts to keep up with the accelerating trend of electrification?

Yutaka welcome your inquiries‼

Sites in Japan

Overseas Sites

If you have any orders or inquiries